Download Full PDF Package. Chemical Process Design and Simulation.

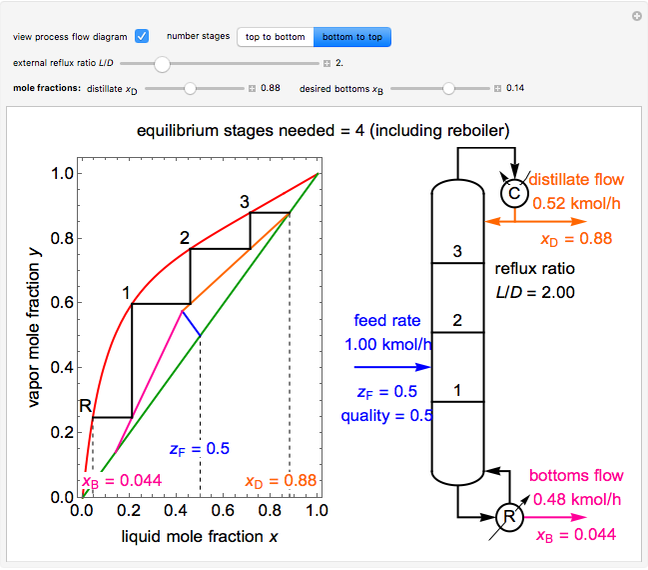

Mccabe Thiele Method For Methanol Water Separation Wolfram Demonstrations Project

The methanol is sent to one of the methanol conversion processes.

. The raw methanol is flashed to separate and recycle the unreacted gas mixture from the liquid methanol mixture. The remaining stream is heated to 80 C in exchanger HX5 and then sent to a distillation column DT1. Download Full PDF Package.

Distillation by filtration In early alchemy and chemistry otherwise known as natural philosophy a form of distillation by capillary filtration was known as a form of distillation at the time. Water balance for a chemical synthesis process manufacturing plant producing paracetamol ratio of consumption of process water to total water 05. Advances to the design and sensitivity of particularly coulo-metric Karl Fischer titrators since Burfields day now allow accurate measurements of water in organic solvents at the ppm level6 The objective of the present study was not to comprehensively cover a wide cross section of drying agents Burfield and co-workers have already adequately per-formed this task.

Waters Alliance 2695 equipped with two pumps pump 1. Design and simulation of a methanol production plant from CO 2. Full PDF Package Download Full PDF Package.

The reactants are placed in a test-tube flask or beaker. Methanol and an Waters XTerra MS C 18 5 µm guard column 10 mm 21 mm coupled to an Alltech Ultrasphere C 18 IP 5 µm column 150 mm 21 mm with a LC Packings ACUrate ICP-04-20 post-column splitter sending a quarter of the column eluate. A short summary of this paper.

The economics consider capital costs energy costs the value of the methanol product and the heating value of a vent stream that is necessary for purging off inert components entering. Methanol comes out of the top at 1 bar and 64 C in gaseous form containing 69 wt. The entrained gases are further separated via a degasser distillation column.

Column and cooler consist of a 5-foot-long 15 m copper tube. To develop the economically optimum design of a methanol reactordistillation column system with three gas recycle streams to produce high-purity methanol from synthesis gas. A short summary of this paper.

1 mM ammonium acetate buffer pH 55 set with acetic acid. Today it is very crucial to develop effective and selective methods for the extraction and isolation of those. A column still also called a continuous still patent still or Coffey still is a variety of still consisting of two columns.

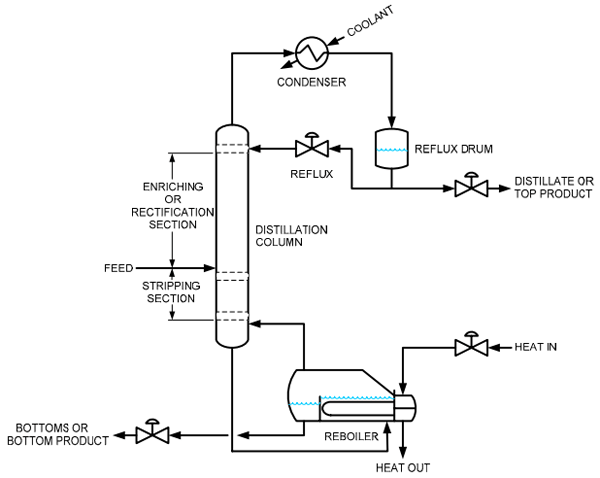

Tray and packed columns are both commonly used for distillation absorption and stripping separation operations. DISTILLATION DESIGN AND CONTROL. 36 Full PDFs related to this paper.

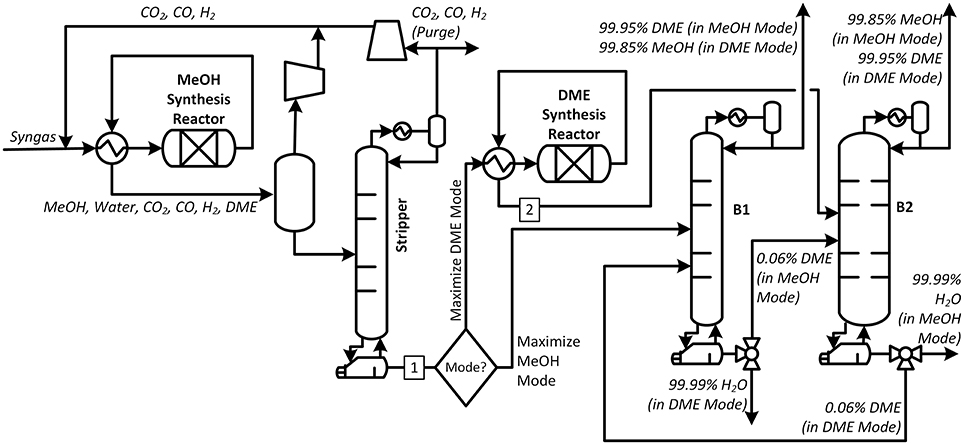

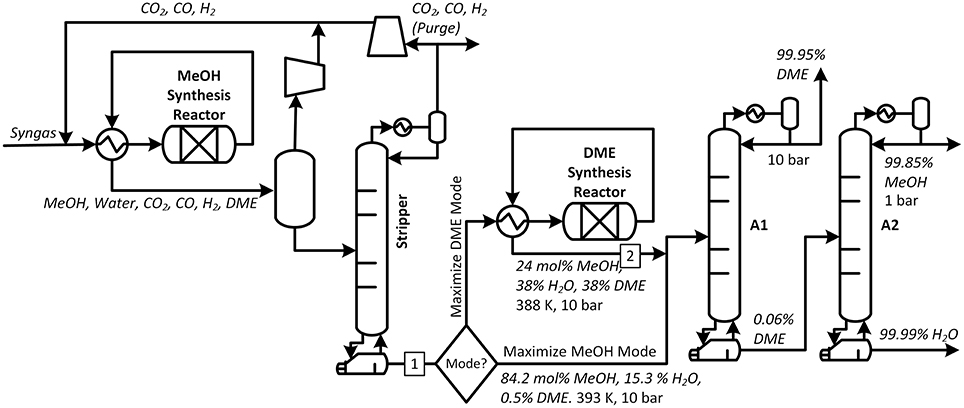

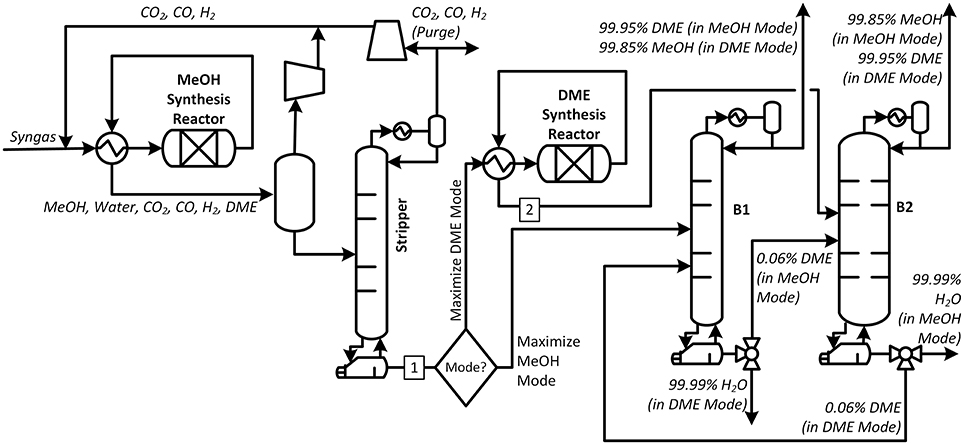

In this a series of cups or bowls were set upon a stepped support with a wick of cotton or felt-like material which had been wetted with water or a clear liquid with each step dripping down. Adapted from ref 31. Methanol produced can either be split to a methanol-to-aromatics MTA reactor or to a.

The amounts of bioactive natural products in natural medicines are always fairly low. Natural products are important sources for drug development. A column still can achieve a vapor alcohol content of 95 ABV.

A spiral still is a type of column still with a simple slow air-cooled distillation apparatus commonly used for bootlegging. 37 Full PDFs related to this paper. The design of the reactor is determined by many factors but of particular importance are the thermodynamics and kinetics of the chemical reactions being carried out.

Batch reactors are used for most of the reactions carried out in a laboratory. Full PDF Package Download Full PDF Package. Natural medicines were the only option for the prevention and treatment of human diseases for thousands of years.

1 2 The goal of this experiment is to distill a mixture of alcohols methanol isopropanol and water in a sieve tray column and examine how closely simple theories of distillation based on equilibrium assumptions are followed. The water comes out of the bottom of the column at 102 C containing 23 wt-ppb of methanol. DOCUMENTATION OF DISTILLATION COLUMN DESIGN.

The two main types of reactor are termed batch and continuous.

Optimization Of The Reflux Ratio For Methanol Water Stage Distillation Column Springerlink

The Methanol Water Distillation Column Download Scientific Diagram

Frontiers The Optimal Design Of A Distillation System For The Flexible Polygeneration Of Dimethyl Ether And Methanol Under Uncertainty Energy Research

Frontiers The Optimal Design Of A Distillation System For The Flexible Polygeneration Of Dimethyl Ether And Methanol Under Uncertainty Energy Research

Frontiers The Optimal Design Of A Distillation System For The Flexible Polygeneration Of Dimethyl Ether And Methanol Under Uncertainty Energy Research

Optimizing Distillation For Increased Methanol Capacity

A Process Integration Approach To The Design Of The Two And Three Column Methanol Distillation Schemes Sciencedirect

Pdf Design And Control Of Extractive Distillation For The Separation Of Methyl Acetate Methanol Water

0 comments

Post a Comment